▸ Products Menu

| Product Examples

| Products by Shape / Manufacturing Process

| Fasteners and Rivets

| FAQ |

Blind Rivets

Home >

Products >

Fasteners and Rivets >

Blind Rivets

Blind Rivet Basics

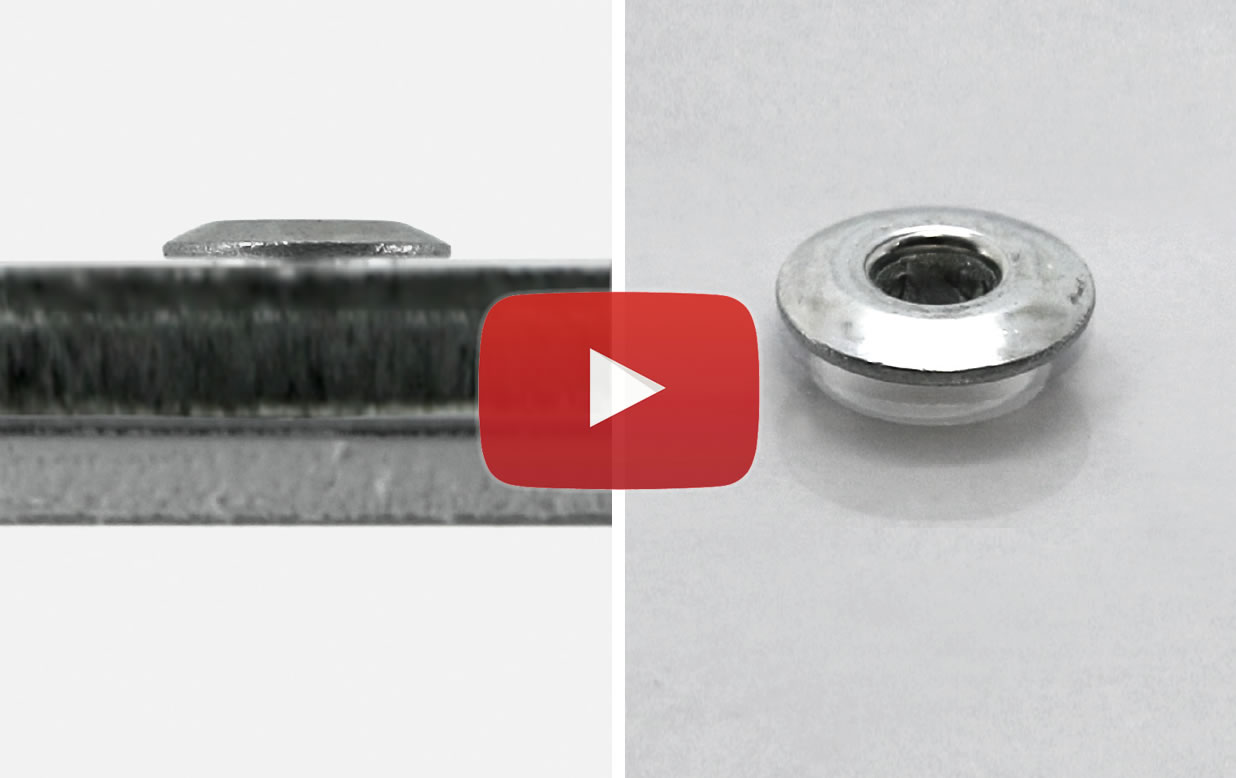

Easy, secure and speedy fastening

Blind rivets offer high speed, reliable riveting. They are also easy to use, requiring just a little training using a riveter (a lightweight hand tool about the size of an electric drill).

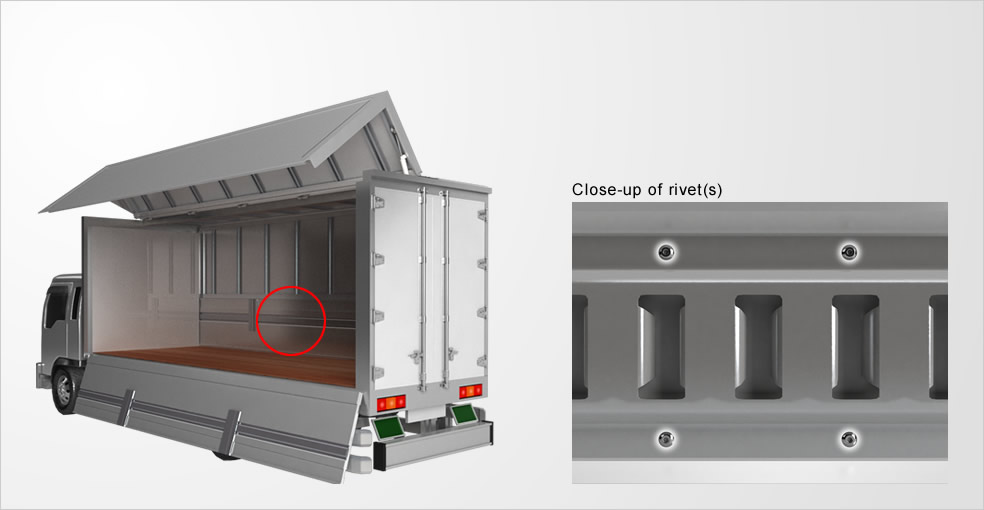

Only need access to one side of an assembly

Blind rivets are ideal for fastening workpieces that can only be accessed from one side, are in tight places, or are large and difficult to handle.

Reliable fastening

Blind rivets provide highly reliable fastening and are used in a variety of industries and applications. They also are ideal for fastening dissimilar materials that are difficult to weld together, such as aluminum and steel.

Reduction in initial investment

Blind rivets only require an inexpensive hand-held riveter to use them and thus require a low initial investment.

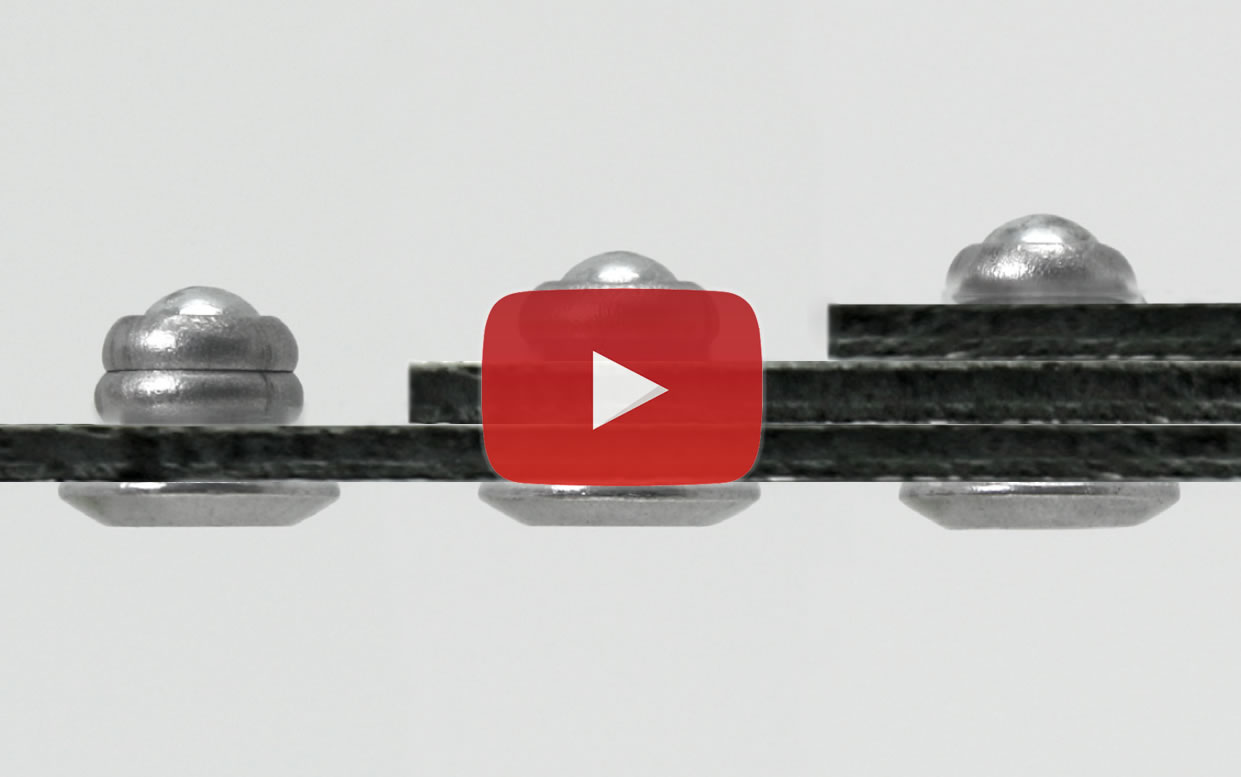

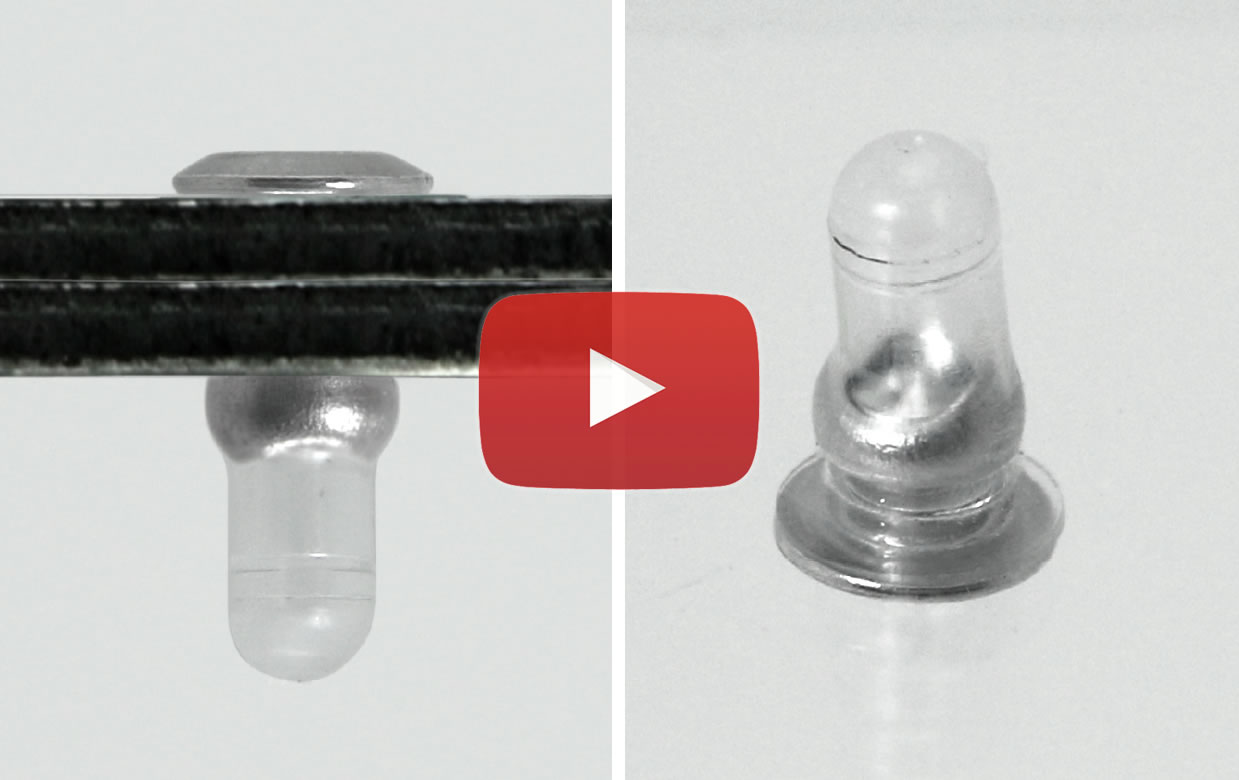

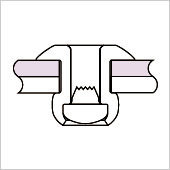

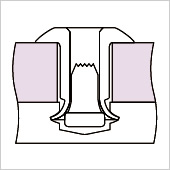

Fastening with Blind Rivets

Types

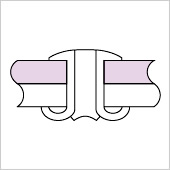

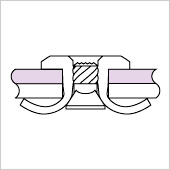

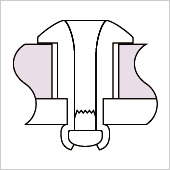

Standard Type

These are the most common type of blind rivet used in various industries and are globally recognized as a standard fastener.

FX type / Various fastening thicknesses

These one-size-fits-all rivets can be used to fasten a wide range of workpiece thicknesses. They have a bright finish and high clamping strength.

GT type / High strength fastening

CP type / Waterproof seal

These rivets utilize a built-in plastic cap to provide waterproof fastening. They also help to prevent galvanic corrosion between the rivet and workpiece.

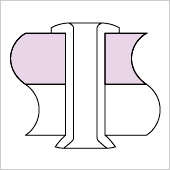

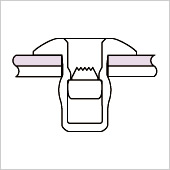

PL type / Fastening soft workpieces

The end of the PL type rivet splits into four petal-like sections. It is ideal for fastening softer workpieces such as plywood or plastic.

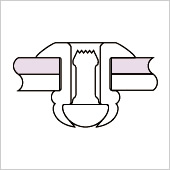

PLX Type ( Mandrel head fixed type )

Best for fastening lighter workpieces together. The head of the mandrel is fastened firmly inside the rivet after fastening (compare to PL type ), this prevents unwanted noise in the final application and reduces swarf.

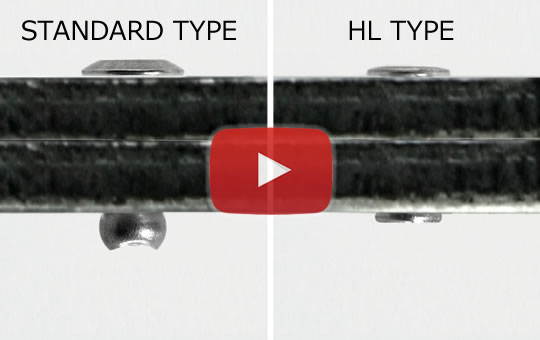

HL type / Lower crumple height

These are the most common type of blind rivet used in various industries and are globally recognized as a standard fastener.

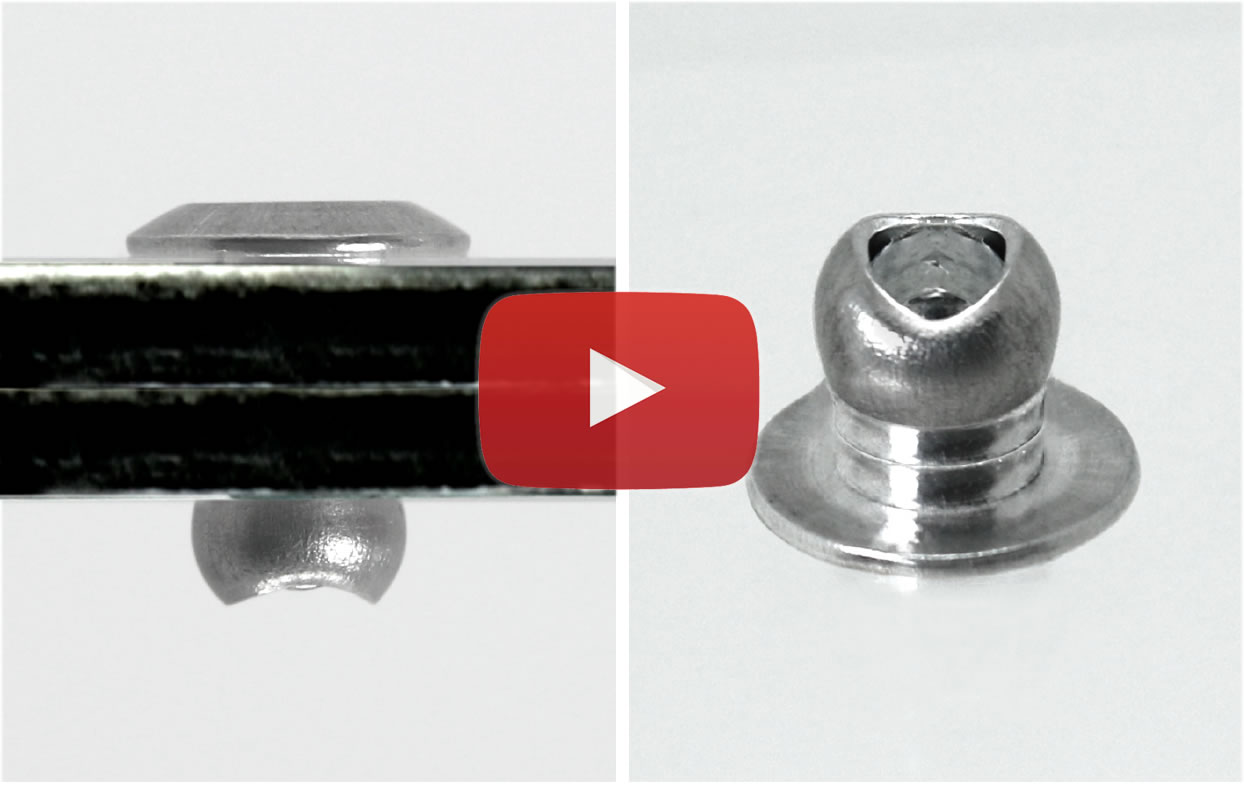

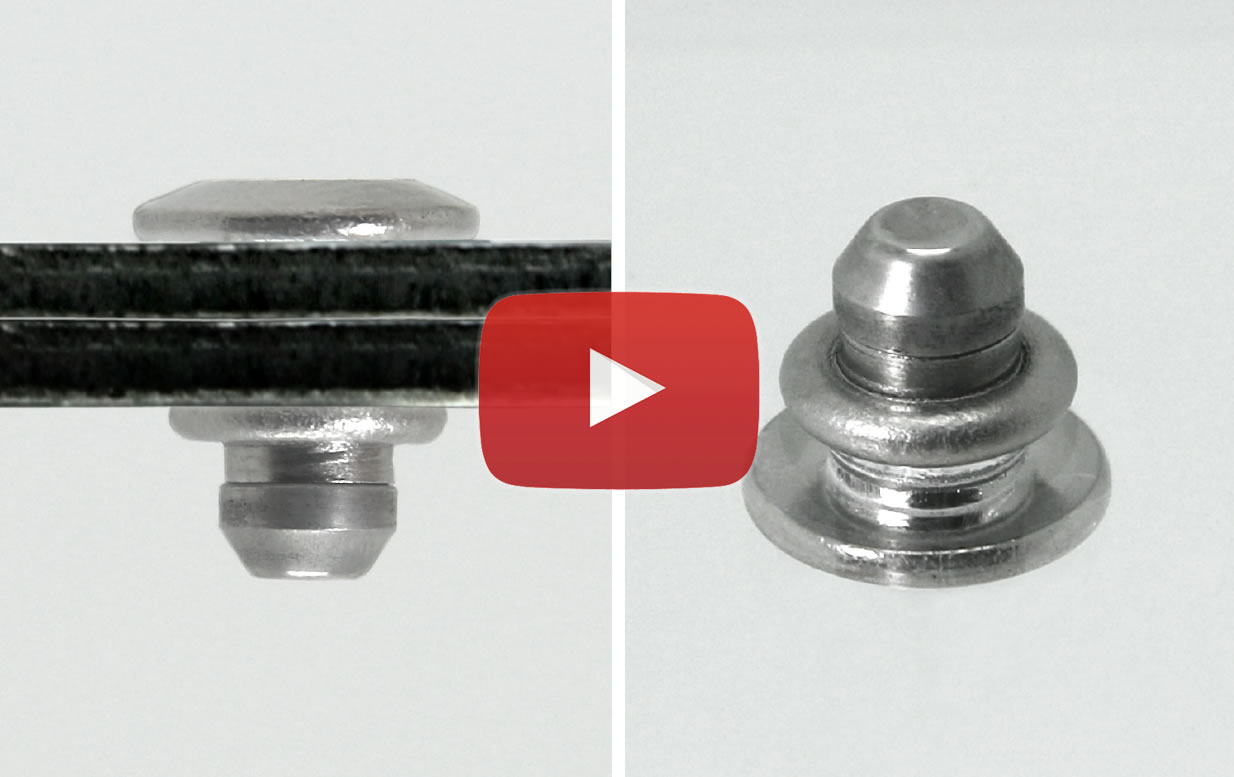

Examples of Customized Blind Rivets

Stepped rivet

Improved-shear-strength type

Conductive rivet

Blind hole fitting type

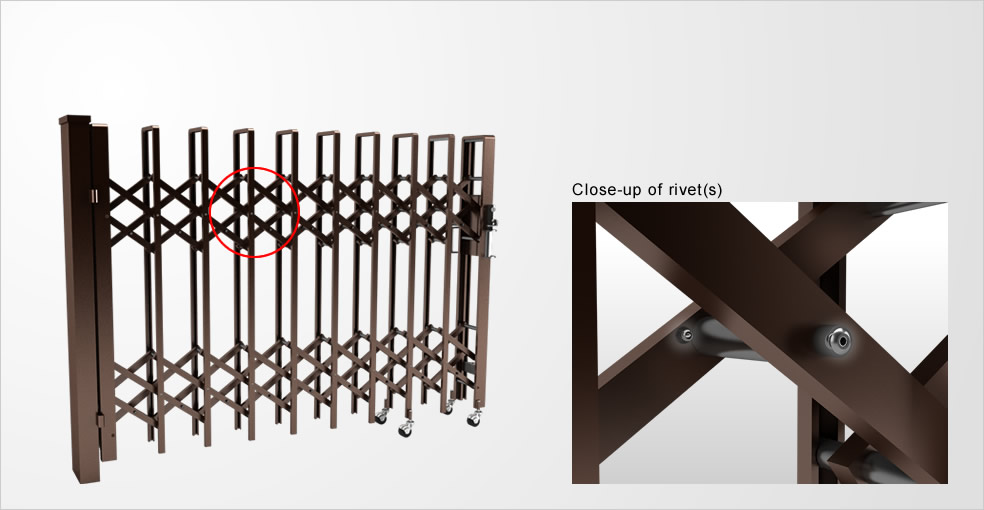

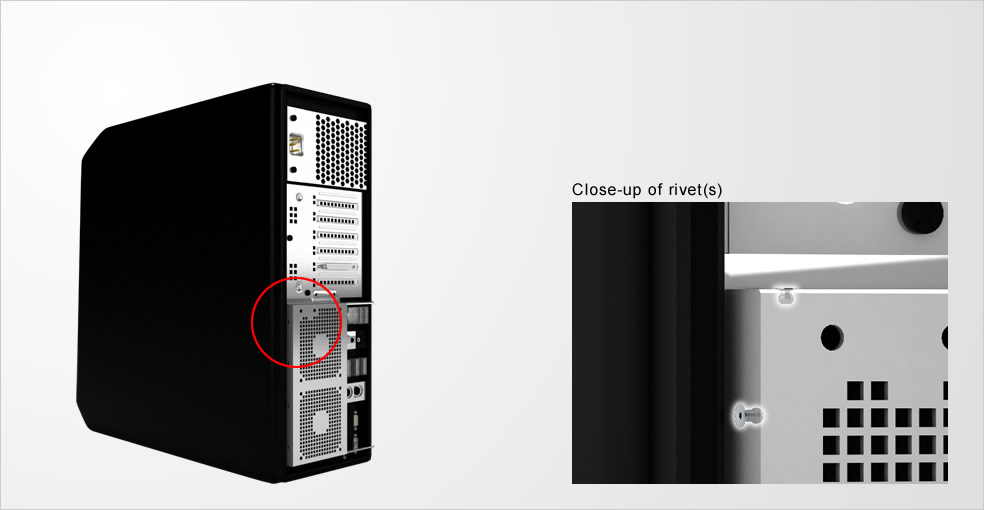

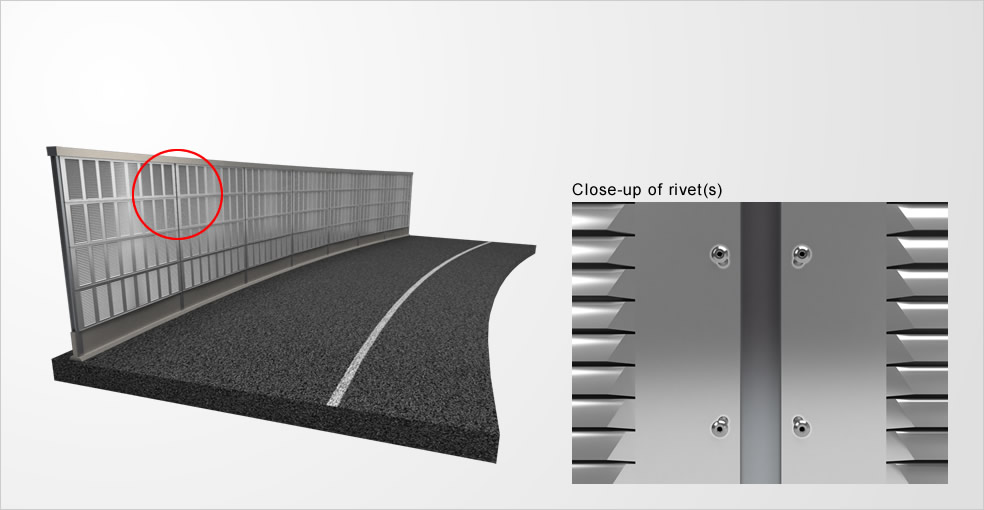

Example Applications for Blind Rivets

PDF DOWNLOAD